The purifier is an integrated purification device designed for industrial waste gas (such as toluene, formaldehyde and other irritating odor exhaust gas) or the production of soot and light particles.

全国服务热线:400-623-1203

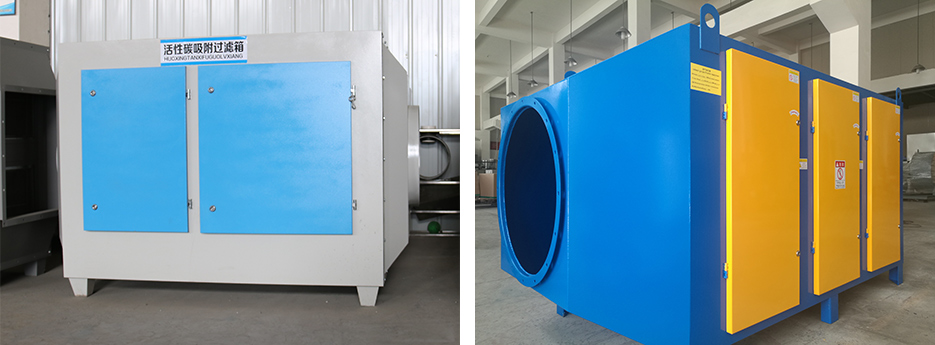

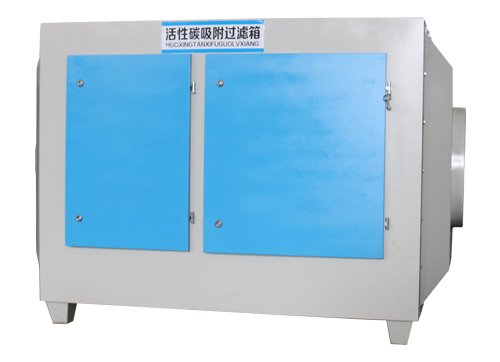

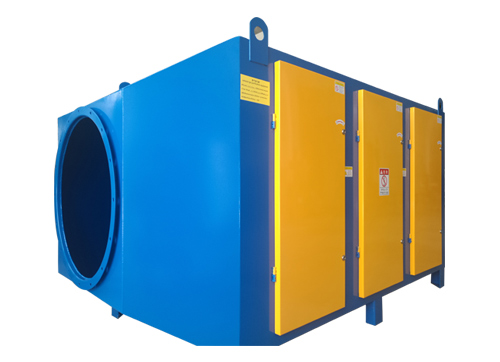

在线咨询| product name: | CLW--HT activated carbon adsorption device |

| Product Category: | Exhaust gas (odor) purification system -> CLW-HT series activated carbon adsorption device |

| Processing volume: | 2000~36000m3/h |

| product advantages: | Integrated structure, reasonable design, high processing efficiency, low cost, operation and maintenance, no secondary pollution |

| Use range: | Flue gas, exhaust gas, odor gas or dust or smoke treatment site |

The purifier is an integrated purification device designed for industrial waste gas (such as toluene, formaldehyde and other irritating odor exhaust gas) or the production of soot and light particles. The core components of the equipment mainly adopt activated carbon adsorption purification device, which can effectively remove the welding fumes and degrade various odors, oil odors and various toxic and harmful gases containing metal ions. Lightweight and flexible, easy to operate.

First, the working principle is as follows:

The equipment is provided with an air inlet and an air outlet respectively. The exhaust gas needs to be purified into the intermediate effect filter through the air inlet. In this treatment area, a mesh medium effect filter (medium effect filter cotton, optional) is provided, and part of the soot or particles in the soot exhaust gas are filtered and intercepted, and then the soot The exhaust gas enters the plate-and-frame type first-stage honeycomb activated carbon filter for initial filtration and adsorption. At this time, most of the heavier dust of the large particles is filtered to the surface of the plate and frame filter, and other odorous gas containing fine particles is filtered from the inner surface of the plate frame filter through the activated carbon layer and discharged from the other outer surface. After confluence, it enters the plate and frame type secondary honeycomb activated carbon filter for efficient filtration, adsorption and deep purification. At this time, most of the fine particles and dust are filtered to the surface of the plate and frame filter, and the untreated odorous gas is filtered from the inner surface of the plate and frame filter through the activated carbon layer and discharged from the other outer surface to the air outlet. The plate-and-frame type activated carbon filter adopts the two-stage series treatment method, which effectively enlarges the contact area of the exhaust gas with the activated carbon and greatly improves the adsorption and purification effect of the exhaust gas.

The primary filter inside the device is fixed at the air inlet of the device. The frame filter is designed with drawers and an access door. The door can be cleaned, cleaned or replaced. The plate and frame filter is installed on a special frame, and a plurality of activated carbon honeycomb sponges form a filtering unit to form a multi-stage purification unit, and then several units are assembled into a chemical filtration section. The metal frame of the plate and frame filter is made of metal and can be reused. This design greatly reduces the user's operating costs.

Second, the scope of adaptation:

Widely used in chemical, electronic, metal processing, tobacco, glass, pharmaceutical, food processing, clean room and other production of exhaust gas or stainless steel and pipe processing, aluminum and other metal welding, such as lead, tin and other flue gas, exhaust gas or Dust or smoke treatment site.