First, product summary function principle introduction A. Main structural principle: The whole structure consists of five parts: automatic slag removal, automatic separation of grease, manual d

全国服务热线:400-623-1203

在线咨询First, product summary function principle introduction

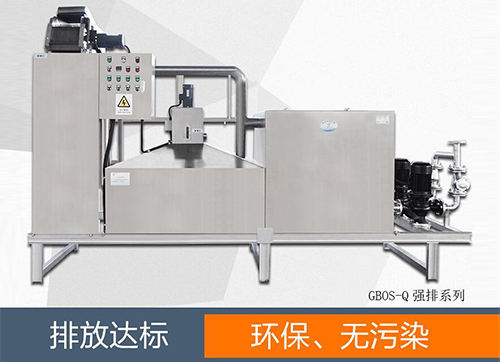

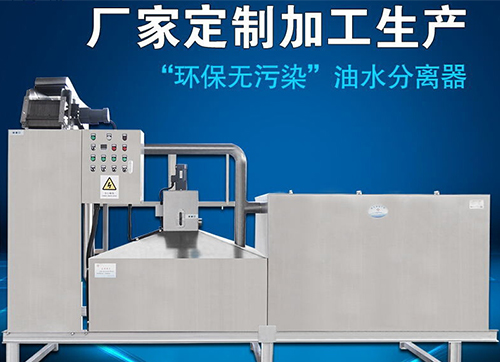

A. Main structural principle: The whole structure consists of five parts: automatic slag removal, automatic separation of grease, manual discharge of grease, advanced treatment of disc type oil and sewage lifting.

The working principle is as follows: when the oily waste water flows into the first isolation zone, the automatic slag removing device intercepts the solid suspended matter (particles and the like) in the sewage through the hinged dragon to stop the slag material in the slag removing container; Entering the automatic separation zone of grease, using the U-tube principle and the pressure difference between the inlet and outlet water of the equipment, the oil and water are separated by the ingenious degreasing structure. After separation, the oil floats up and collects at the top of the vertebral separation chamber. The grease can be drained regularly into the waste oil drum by the manual oil drain valve installed here. The waste oil drum should be cleaned or replaced regularly by a special person.

After the oil slick is removed, the sewage enters the disc treatment area from the damper. At this time, the effluent still contains a small amount of water-soluble grease and suspended oil and granules. The final separation of the water and oil can be completed through the filtration and decomposition of the biochemical filter. The sewage is separated from the bottom of the treatment filter from the bottom to the top, and the layers are decomposed. In this process, sewage is introduced from the inlet holes of each layer of the treatment filter. Due to the unique surface area of the filter and the structural design of extending the length of the intercepting cofferdam, the flow rate of the sewage is quite slow. At the same time, through the blocking of the small gap between each layer of the chip, the fine slag wrapped by the grease can be intercepted and filtered, and then the sewage is taken from each The chip overflow port is collected into the longitudinal water outlet channel, and finally flows from the longitudinal water outlet channel through the filter outlet to the sewage lifting zone, and finally to the outdoor municipal pipe network.

The oily sewage is continuously treated to remove the oil scum and isolate the suspended particles, thereby achieving the purpose of oil-water separation.

Emergency lift pump: When there is water in the pool, the sewage will be pumped out automatically to avoid accumulation of water in the foundation pit of the equipment.

B. Main features:

1. Combined with slag removal, degreasing and disc treatment to strengthen the sewage, the pollutant removal efficiency is high, and the effluent effect is good.

2. Advanced technology and high degree of automation: the slag removal adopts hand/automatic control, and the slag removal and slag removal structure is unique, the design is new, and the new design idea is introduced from the traditional structure, which reflects the leading in the similar products. status.

3. The system adopts unpowered automatic degreasing technology, which has low operating cost and is extremely simple and convenient to maintain and use.

4. It adopts the above-ground installation method, with small floor space, low construction cost and convenient construction and installation.

5. Simple structure and stable use, it is favored by large and medium-sized star hotels, office buildings, tourist resorts or food courts, and has become a new environmentally friendly product to replace ordinary grease traps.

6. The oil slick and sediment are relatively concentrated, which is convenient for collection and clearing, creating conditions for the formation of high-efficiency, enterprise-type and centralized waste collection in the future, and effectively avoiding secondary pollution.

Second, product technical parameters:

| Model item | Catering wastewater automatic slag separation and oil separation machine CLW- OWS-ZZY-T type |

| 1. Appearance size of the device | Determined by model or site |

| 2. Rated treated water volume | 1.0-50m3/h |

| 3. Equipment main material | SUS304 stainless steel |

| 4. Degreasing amount | 1.0-50 (liters) |

| 5. Total power consumption | Determined by model |

| 6. Weight (KG) | Determined by model |

| 7. Types of electrical appliances | Motor, emergency pump, etc., determined by model |

Note: Due to continuous technical changes, the above parameters are not in accordance with the actual product, without prior notice, subject to the actual product.

Third, the operation and precautions

1. The main operation of this device is circuit control system operation, and the control settings are divided into manual, automatic and stop functions.

2. When the selector switch is set to the manual gear, the continuous operation is performed; when the automatic gear is used, the operation is controlled via the time controller (ie, the microcomputer time control switch control). As far as possible, please select the automatic file to run the control to make the gap operation to improve the efficiency of the equipment.

3. The operation time setting of the slag grilling machine can be set according to the discharged sewage, the amount of suspended solids in the water, the running time or the time setting of the sewage discharge during the use of the kitchen, that is, the sewage starts when the sewage enters the equipment. . However, it is not advisable to work continuously 24 hours a day. When the kitchen is not in use or there is no sewage, it is set to stop running. This will help protect the motor and extend the life of the motor. Under normal circumstances, the kitchen is used during the day, the grille can be set to work continuously during the day, after 10 pm (or depending on the actual time when the kitchen is not used) to 10:00 the next day (or depending on the kitchen) The time can be set according to the actual situation.

4. The system adopts hydraulic mode to manually drain oil: when manually discharging, the instantaneous flow rate of oil discharge is relatively large, and it is necessary to slowly open the oil discharge valve and drain the oil; when a small amount of sewage appears, close the oil discharge valve to stop the oil discharge.

5. Oil drain cycle setting: Under normal circumstances, the manual oil drain cycle is 1 time / 2 days or adjust according to the actual situation. When starting to use for 1~2 weeks, the oil accumulated in the separation chamber is less able to be discharged, which is normal. phenomenon.

6. When installing this system, the base surface of the base must be leveled to ensure that the oil level of the oil drain is maintained at a level to achieve the best oil discharge effect.

7. In the slag removal and degreasing areas, impurities such as plastic bags, fabrics, and fabrics are prevented from entering the area, resulting in poor slagging, oil discharge and drainage, and blockage of internal piping of the equipment.

8. After the machine has been in operation for a period of time, if there is too much sediment or debris in the degreasing zone or the degreasing zone, it should be cleaned and emptied in time.

9. pay attention:

1). If the thickness of the sediment in the slag area or the degreasing area is more than 250mm, the water hole will be blocked and the drainage will be poor, resulting in overflow of the sewage. Please clean up and remove it in time (normally: the bottom of the slag area) 1 time / 2 months; 1 time / 2 months at the bottom of the deoiling area or as the case may be), removal tool: sanitation powder truck or similar suction truck.

2) When installing this system, it must be ensured that there is no water in the foundation pit of the equipment, and it is very important to ensure that the equipment (especially the slag removing motor) is not flooded, which may cause motor damage and induce electric shock.

Fourth, common faults and elimination

1. The slag removal motor works, no slag discharge or sewage discharge from the slag discharge port:

Reason 1: The slag slinger is blocked and the water level is raised.

Countermeasures: Clean up the internal garbage of the hinged dragon. When there is more garbage at the bottom of the equipment, the water level will rise and the sewage will flow out from the slag discharge port of the slag removal machine.

Reason 2: There may also be no slag in the sewage.

2. When the machine is running, the oil in the tank will not come up.

Cause 1: The sewage liquid level has not reached the draining liquid level, the oil discharge port is blocked or the drain pipe is blocked.

Countermeasure: Wait for the liquid level to rise to the working level.

Reason 2: There are impurities in the oil drain area.

Countermeasure: Remove debris from the inspection port.

3. The water overflows directly from the slag tank or equipment cover.

Reason 1: The water volume at the inlet exceeds the rated treatment water volume.

Countermeasures: Please reduce the amount of water in the water inlet, and the control is not greater than the rated treatment water volume.

Cause 2: The slag removal tank and the drain sump are blocked.

Countermeasure: Manually clean the blockage in the tank (the main reason is that it will not be maintained for a long time, and the precipitated debris accumulated in the tank will not be cleaned up in time).

4. Please contact our company for repairs.

Five, daily use precautions and maintenance

Precautions! ! !

The slag-containing oil sewage is discharged into the kitchen ditch. The kitchen ditch must be provided with a multi-layer filter to isolate the larger, harder and sharper residue solids in the water, especially construction waste stones and sand; broken tableware such as tableware , cutlery, plastic fabrics, steel balls, etc.

Sixth, daily maintenance:

1. Check the equipment regularly to see if it is working properly. It is recommended to do it at least once a week.

Firstly, check whether there is excessive volume of solid suspended solids in the slag sump. If there are any solid objects that cannot be cleaned out in the gap or surface of the slag mesh, if it is found, it must be cleaned in time to prevent blockage. The equipment is not well drained.

2. The equipment is operated for more than 2 weeks or depending on the actual situation. It is necessary to clean the inside and outside of the equipment. Mainly for the inner and outer walls of the tank, the slag discharge port, the oil discharge port, the filter element (disc processor), the water outlet, etc., to prevent the oil stain from adhering to the groove wall and solidified agglomerate or block the pipeline, hindering the normal operation of the equipment.

3. After the equipment is operated regularly or according to the actual situation, the sediment or sludge at the bottom of the equipment shall be completely removed in time.

4. Entrust a professional electrician to conduct a comprehensive inspection of the system circuit, connectors or electrical equipment on a regular basis to ensure the safe operation of the system.

Special Note: This equipment is forbidden to use in the unmanned maintenance state for a long time!

This manual is for reference only. According to the customer's requirements and the actual situation of the installation site, the company has the right to change the original product specifications and structural design without prior notice!

The company has the final interpretation, thank you for your cooperation and support!

Jiangsu Klewei Environmental Protection Equipment Engineering Co., Ltd.

National unified customer service phone: 400-623-1203