The integrated sewage treatment equipment is a device that integrates a settling tank, I and II level contact oxidation tanks, secondary sedimentation tanks and sludge tanks, and performs blast

全国服务热线:400-623-1203

在线咨询The integrated sewage treatment equipment is a device that integrates a settling tank, I and II level contact oxidation tanks, secondary sedimentation tanks and sludge tanks, and performs blast aeration in the I and II grade contact oxidation tanks to make contact oxidation. The method and the activated sludge method are effectively combined, and both have the advantages of both, and overcome the shortcomings of both, so that the sewage treatment level is further improved.

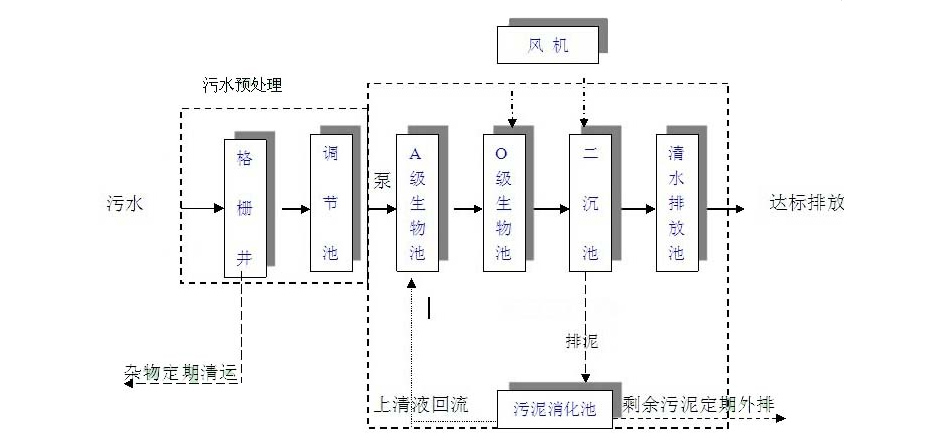

Introduction: There are many sewage treatment processes adopted at home and abroad, which are mainly divided into activated sludge method and biofilm method. Our common common aeration method, oxidation ditch method, A/B method and A2/O method belong to the former. The biological turntable and the contact oxidation method belong to the latter. The integrated sewage treatment equipment is a device that integrates a settling tank, I and II level contact oxidation tanks, secondary sedimentation tanks and sludge tanks, and performs blast aeration in the I and II grade contact oxidation tanks to make contact oxidation. The method and the activated sludge method are effectively combined, and both have the advantages of both, and overcome the shortcomings of both, so that the sewage treatment level is further improved.

ADVANTAGE

1. The ability to withstand impact load is strong, and the average residence time of the contact oxidation method is more than 6 hours.

2. It has the ability of denitrifying and dephosphorizing, and can realize the ability to treat industrial wastewater, domestic sewage and urban sewage by adjusting the structure of the equipment.

3. The fillers in the contact oxidation pond are mostly combined soft fillers, which are light in weight, high in strength, stable in physical and chemical properties, large in specific surface area, strong in biofilm adhesion, and high in contact efficiency between sewage and biofilm.

4. In the contact oxidation tank, an aerator is used for blast aeration, so that the fiber bundle is continuously floated, the aeration is uniform, the microorganisms grow mature, and the characteristics of the activated sludge method are obtained.

5. The effluent water quality is stable, the sludge production is small and easy to handle.

6. The submersible pump can be installed in the equipment to reduce engineering investment.

7. The equipment can be located on the ground or buried in the ground. When buried in the ground, the upper cover can be used for greening, the plant area is small, and the ground structure is small.

8, easy to complete automatic control, management and operation is simple.

9. The equipment can be connected to the car to make a mobile integrated sewage treatment equipment.

SCOPE OF APPLICATION

The integrated sewage treatment equipment is suitable for domestic sewage, such as residential quarters, villages, villages, office buildings, shopping malls, hotels, restaurants, nursing homes, institutions, schools, military units, hospitals, highways, railways, factories, mines, tourist attractions, etc. Similar processing and reuse of small and medium-sized industrial organic wastewater such as slaughter, aquatic products processing, and food. The sewage treated by the equipment meets the national sewage treatment comprehensive discharge standard.

The main components are: 1. Hydrolysis acidification tank; 2. Contact oxidation tank; 3. Impurity sedimentation tank; 4. Disinfection treatment

HYDROLYSIS ACIDIFICATION TANK

The main treatment of this process is to pre-treat the sewage before treatment, and carry out certain anaerobic fermentation of the wastewater in the water to improve the biodegradability of the sewage. This is an important step before the sewage treatment, which can directly affect the later sewage. The efficiency of the treatment and the processing time can maximize the efficiency of wastewater treatment and reduce consumption.

2. CONTACT OXIDATION POOL

Oxidation tanks are divided into several grades according to the degree of pollution of water treatment, common type and enhanced type. It is generally judged based on the processing time. A normal type oxidation pond is used for a treatment time of no more than four hours, and a reinforced oxidation tank is used for a treatment time of between 4 and 6 hours. Mainly use the effluent from the hydrolysis acidification tank to the contact oxidation pond for biochemical treatment. Most of the organic matter in the raw sewage is degraded and purified here. The aerobic bacteria uses the filler as the carrier, and uses the organic matter in the sewage as the food material to decompose the organic matter in the sewage into inorganic salts, thereby purifying the object. The survival of aerobic bacteria must have sufficient oxygen, that is, there is enough dissolved oxygen in the sewage to achieve the purpose of biochemical treatment. The aerobic pool air is provided by the fan, and the tank adopts a new elastic three-dimensional filler. The filler has a large surface area ratio, long service life, easy to hang membrane and corrosion resistance, and the bottom of the pool adopts a rotary mixing aerator to make the transfer rate of dissolved oxygen high. At the same time, it has the advantages of light weight, no aging, no clogging, and long service life. The gas-water ratio of the contact pool is around 12:1. (0.5-5 m3/h contact pool is level 2)

3. IMPURITY SEDIMENTATION TANK

After the sewage is treated by the biological contact oxidation pond, the effluent flows into the sedimentation tank and further precipitates and removes the fallen biofilm and some organic and inorganic small particles. The sedimentation tank is based on the principle of gravity, and the sewage containing the suspended matter flows from bottom to top. At the time, the substance is precipitated by gravity. The upper part of the sedimentation tank is provided with adjustable water rafts to adjust the water level; the lower part is provided with a conical sedimentation zone and a sludge gas device, the gas source is provided by a fan, and the sludge is sent to the sludge aerobic digester by gas stripping.

4. DISINFECTION

The disinfection tank is 30 minutes according to the standard. If it is hospital sewage, the disinfection tank will increase the residence time to 1-1.5 hours. Our company adopts chlorine dioxide disinfection device. The disinfection tank and disinfection device can continuously change the dosage according to the amount of water. It can achieve more water and more medicine, less water and less medicine. Other equipment can be prepared separately. (If used in industrial sewage, disinfection tanks and disinfection devices may not be used.)