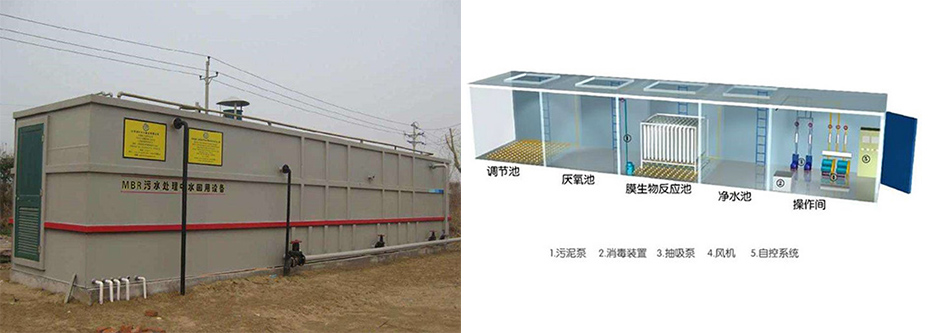

The CLW-MBR membrane bioreactor integrated equipment is a new type of water treatment technology that combines membrane separation technology and biotechnology. It uses membrane separation equipment

全国服务热线:400-623-1203

在线咨询PRODUCT DESCRIPTION

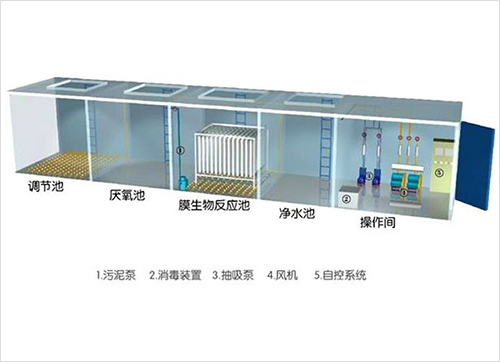

The CLW-MBR membrane bioreactor integrated equipment is a new type of water treatment technology that combines membrane separation technology and biotechnology. It uses membrane separation equipment to trap activated sludge and macromolecular organic matter in biochemical reaction tanks, eliminating the need for secondary sedimentation. Pool. The membrane-bioreactor process greatly enhances the function of the bioreactor through membrane separation technology, which greatly increases the concentration of activated sludge, and its hydraulic retention time (HRT) and sludge residence time (SRT) can be controlled separately.

FEATURES

1) High removal rate of pollutants, strong ability to resist sludge expansion, stable and reliable effluent quality, and no suspended matter in effluent;

2) The membrane bioreactor realizes the separate control of the reactor sludge age STR and the hydraulic retention time HRT, so the design and operation thereof are greatly simplified;

3) The mechanical retention of the membrane avoids the loss of microorganisms, and the high sludge concentration can be maintained in the bioreactor, thereby increasing the volumetric load, reducing the sludge load, and having a strong impact resistance;

4) Due to the long SRT, the bioreactor plays the role of “sludge nitrification tank”, which significantly reduces sludge production, low residual sludge production and low sludge treatment costs;

5) The SRT is prolonged due to the interception of the membrane, creating a microorganism that is beneficial for slow proliferation. For example, the environment in which nitrifying bacteria grow can improve the nitrification ability of the system, and at the same time, it is beneficial to improve the treatment efficiency of the refractory macromolecular organic matter and promote its complete decomposition;

6) The activated sludge in the MBR aeration tank will not be lost with the water. During the operation, the activated sludge will change due to the change of the concentration of the entering organic matter, and achieve a dynamic balance, which makes the system effluent stable and impact resistant. Characteristics of the load;

7) The larger hydraulic circulation leads to the uniform mixing of the sewage, so that the activated sludge has good dispersibility and greatly increases the specific surface area of the activated sludge. The high dispersion of activated sludge in the MBR system is another reason for improving the effectiveness of water treatment. This is difficult to compare with the formation of larger bacterial micelles by common biochemical water treatment technology;

8) The membrane bioreactor is easy to integrate, easy to implement automatic control, and easy to operate and manage;

9) The MBR process omits the second settling tank and reduces the floor space.

APPLICATION RANGE

Membrane bioreactor is a new type of high-efficiency wastewater treatment technology that combines membrane separation and biological treatment. The denitrification mechanism of industrial nitrogenous wastewater includes two basic processes of nitrification and denitrification. Nitrification refers to the process of conversion from ammonia to nitrate, which is mainly accomplished by two types of aerobic autotrophic bacteria, nitrosating bacteria and nitrifying bacteria.

The CLW-MBR membrane technology first removes biodegradable organic pollutants from water by activated sludge, and then uses membrane modules to forcibly retain the activated sludge in the bioreactor and most of the suspended solids to achieve purified water and activated sewage. The separation of mud and solid liquid enhances the biochemical reaction and improves the sewage treatment effect and effluent quality.

The CLW-MBR treatment process has obvious effect on COD treatment in wastewater of nitrogen fertilizer industry. The biochemical strains have a short period of health and domestication, and the stable effect appears from the third day; the COD removal can be maintained in the stable treatment stage and normal operation stage. The rate and removal rate are basically above 90%; the average COD of export is controlled below 30mg/L.